Within the specialized sectors of insulator and rubber track manufacturing, the need for precise application is paramount. At Dekuma, our work centers on building equipment that meets these distinct production challenges. As a custom rubber machine manufacturer, our objective is to deliver solutions that align with specific material and output requirements. The architecture of our custom rubber machine designs reflects this targeted intention.

German-Enhanced Engineering

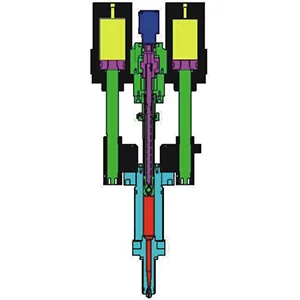

The core of our custom rubber machine performance lies in the plasticizing and injection system. This unit received direct optimization from German technical consultants, ensuring its mechanics adhere to a high standard of operational logic. For instance, the screw is programmed to reduce its speed automatically before plasticizing completes. This attention to detail, along with the feature of an easily disassembled injection piston, supports consistent material processing. This level of control is what defines a Dekuma custom rubber machine.

Adjustable Process Control

A significant feature we provide is granular control over the injection phases. The system includes three separate injection zones, each with independent adjustments for pressure and speed. Furthermore, three dwell zones offer the same level of customizable settings. This allows manufacturers to fine-tune the entire molding cycle with a high degree of accuracy. For a custom rubber machine manufacturer, offering this depth of process adjustment is necessary for complex production runs in subdivided fields.

Dekuma builds machinery with a focus on specific industrial applications. The technical attributes of our systems, from German-guided design to multi-zone adjustability, are intended for manufacturers who require more than a standard solution. Our role as a custom rubber machine manufacturer is to provide the tools for specialized production.